3D Scanning Overview

Wilvern Motorsport is pleased to be able to provide bespoke 3D scanning services.

Utilising our state-of-the-art, non-contact, high definition hand held 3D Scanner, we can quickly and confidently 3D scan your car, product, or project with metrology grade accuracy of 0.02mm1 in any evironment2.

With our 3D scanning service we can provide:-

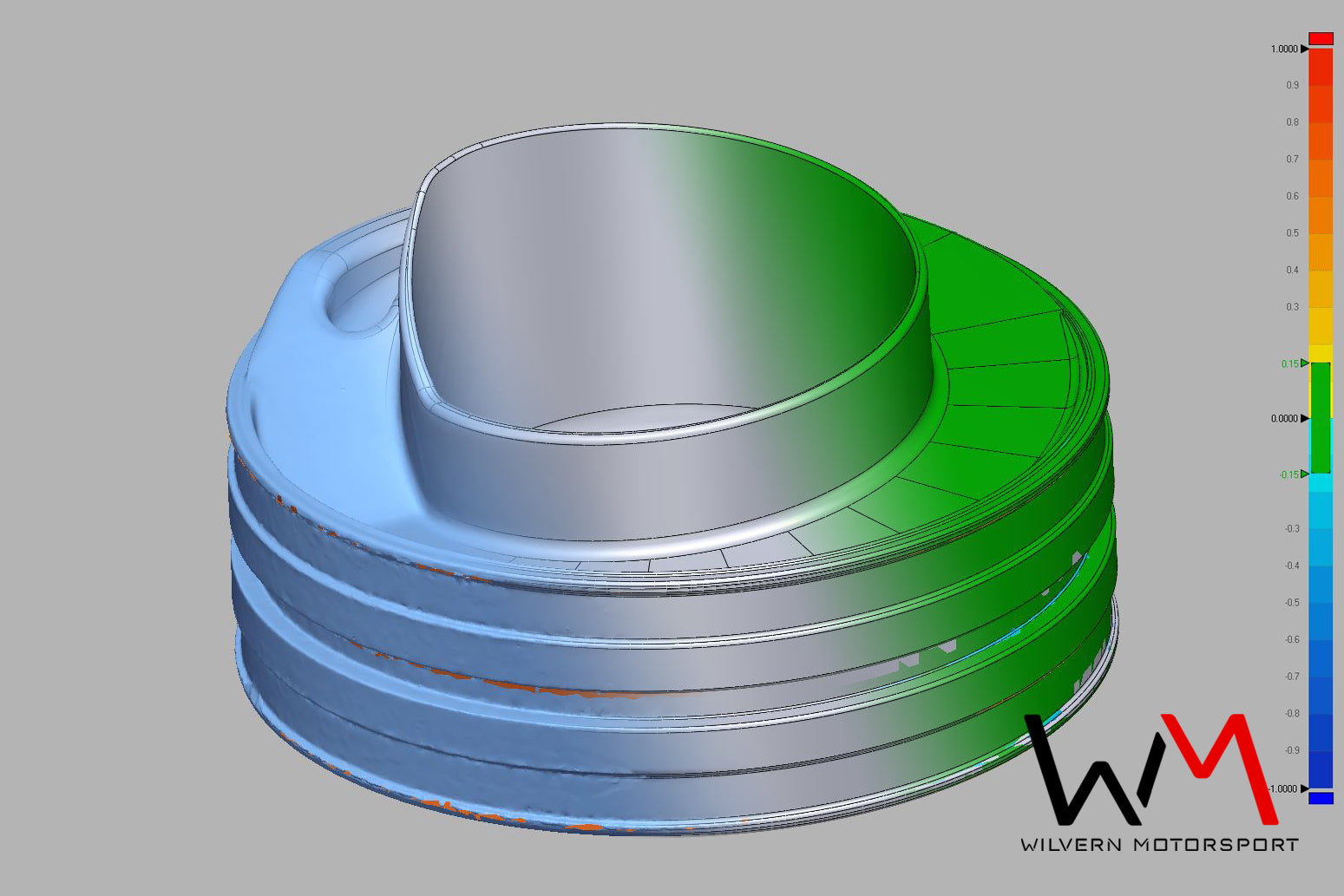

- CAD comparison services:

- Detailed reports to suit customer requirements

- GD&T analysis

- Part dimensional accuracy analysis against CAD model

- Surface data capture:

- Point cloud and meshed data, effectively enabling you to 'rent' the 3D Scanning service if you are able to do your own CAD

- Watertight mesh:

- STL file directly from the optimised scan data, suitable for direct replication of an object (3D Printing / CNC Milling / etc.)

- Reverse engineering:

-

Parametric surface and solid model creation for parts to be modified / reproduced by the customer

- Contract engineering:

- Hire Wilvern Motorsport to see your project through from your idea to delivered CAD, drawings, and support with manufacture. We will be with you every step of the way

Our hand held laser scanner is connected to our powerful CAD laptop meaning we can scan anywhere from on-site in your workshop, in our office, or in the field. We can go wherever the job is!

With a scan area of 225mm×250mm we can quickly work over the part capturing 265,000 points per second, creating a high definition scan in a short amount of time.

Scanning takes more time the bigger the object is and each project is unique. However, to give an idea of how long each component can take we have given a few examples below. These times include applying target markers, scanning the part, and removing the markers.

- Both sides of a car bonnet would take approximately 1.75 hours.

- The racing gearbox project took around 2 hours.

- The Mazda 727C exterior project took approximately 5-6 hours.

For a closer look at our 1984 Mazda 727C exterior project, where the exterior surfaces of a Le Mans race car were turned into a 3D CAD surface model click here.

To look at a reverse engineering example, where we took the gearbox from the race car above and turned into a solid CAD model click here.

Before scanning your project we will determine the compatability with our scanning solution and advise if any special steps will need to be taken.

For example, with gloss black and reflective objects we may need to cover the object with our chosen developer spray to facilitate the scan.

After extensive testing, our chosen developer spray is the AESUB blue solution.

We prefer this over other coatings thanks to its advantages features such as:-

- Disappearing state of the art technology

- No cleaning required

- Thin and homogeneous coating

- Free of pigments

- Developed and approved by scanning experts

Once sprayed onto the object, we can successfully scan the part and within hours the spray will completely dissapear leaving the part exactly as it was before the scan, with no cleaning required.

From full cars to small intricate components we can facilitate your requirements.

Lamborghini air lift / coil spring seat Custom BMW Top Mount Lamborghini air lift component

Based just 30 minutes from the famous Nürburgring in Germany, most of our customers are based in the motorsport sector, however we do offer our services outside of the automotive sector, including aerospace & agriculture. We are also happy to travel to provide services and have completed several projects in Great Britain, The Netherlands, Belgium & ofcourse within Germany.

Often our customers use our services to scan a vehicle or component, give us a brief of what they would like fitting to the vehicle or how it should be fitted, and then we use the scanned data to reverse engineer the components involved and create the solution in CAD. We then 3D print the part on our suite of large platform printers to test fit and gain approval from the customer. At this point the files can be securely transferred to the customer or to their nominated supplier with our ongoing support, or batch produced by us in Germany or Great Britain.

For a unique quote for your project, or if you have an idea that could benefit from our technology & experience, get in touch today by dropping us an email or using the Contact Us page.

1 Accuracy - 0,02mm ± 0,08mm/m

2 Extremely dusty and dirty environments are not always suitable depending on the object to be scanned

This web page is best viewed on desktop with a minium width of 1200px